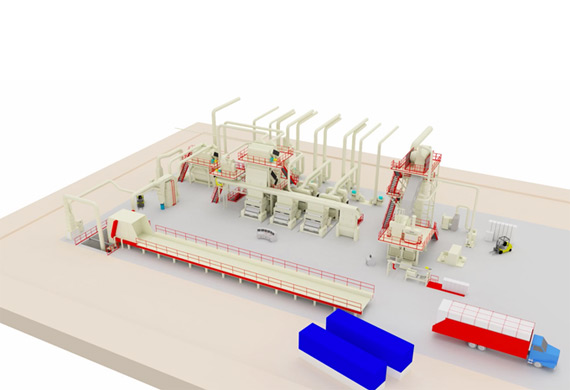

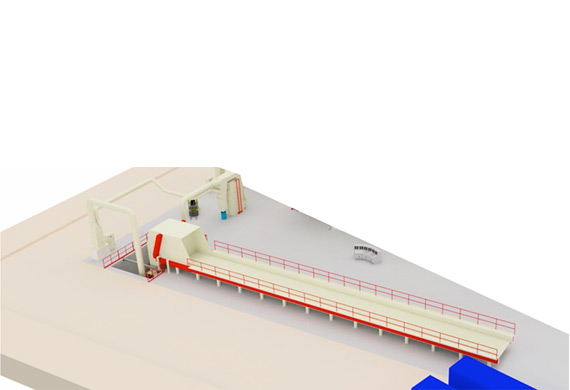

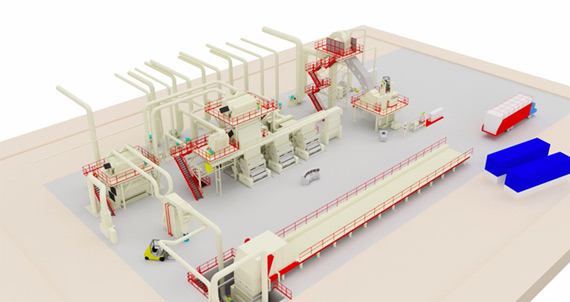

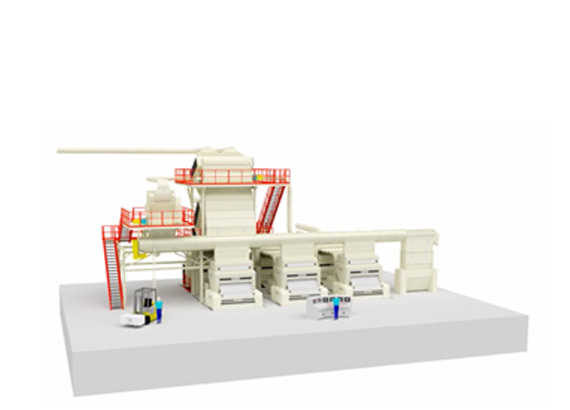

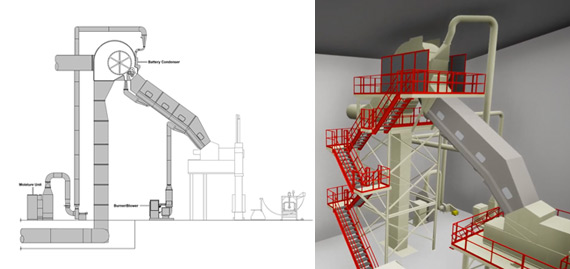

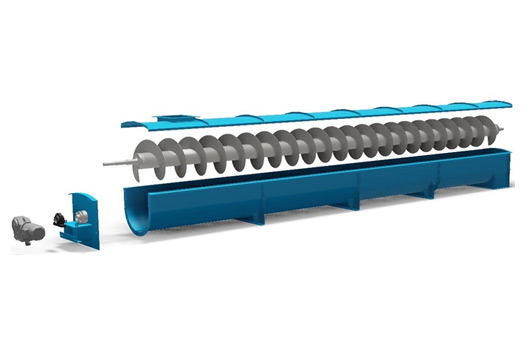

CNIP provides best services for installation of old cotton ginning machinery and restart the cotton ginning machinery. we provide installation of Roller ginning machine, Saw ginning machine & Rotobar roller ginning machine along with machinery installation, bale press installation, construction / foundation work, electrical work, Pipe line works, installation of moisture systems, storage rooms, maintenance room, installation of the tool room machinery which provided by client, Our technical team visit the site and provide best site support to our clients. Generally Seed Cotton Unloading, Cotton Pre-Ginning,Cotton Feeding, Cotton Lint cleaning, Cotton Condensing moisture, Cotton Bale packing & Cotton seed distribution is same for all they ginning systems, only change was roller, saw or Rotobar ginning machine.