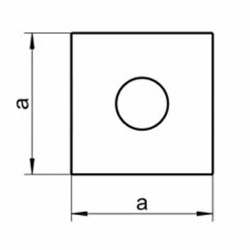

Due to their flat sides( they could be flat on both sides or one side flat with the other being bevelled), stainless steel square washers are designed to prevent rotation. They tend to fit in restricted spaces, unlike their round counterparts, which are not accommodated. Square shaped washers that have one side flat with the other side being sloped, is known as stainless steel square beveled washers. Beveled washers also referred to as a levelling shim, is used for structural support, in applications such as with l-beams.

Generally, they are made from metals like aluminium, copper, brass Bronze, zinc or plastic materials (nylon, polyethylene, Teflon). Washers can also be made from different grades of alloys and steel. stainless square washers manufactured from alloys or steel tends to be stronger and far superior as compared to just plain metals or plastic ones. For example, the 316 stainless steel square washers have a high tensile strength, good resistance to corrosion, good resistance to wear and tear. Hence, they can be used in equipment’s that require their parts to resist corrosion with the ability to withstand tough conditions.

Although the application and end use of the product determines the type of washer to be used in the service. The 1/2 stainless steel square washer is commonly used in construction, machinery, and automotive applications. Stainless steel square plate washers are often coupled with square head bolts. Stainless steel square flat washers prevent pull through and provide a larger surface area. In comparison to standard round flat washers, the stainless steel skid plate washers have a greater holding capacity.