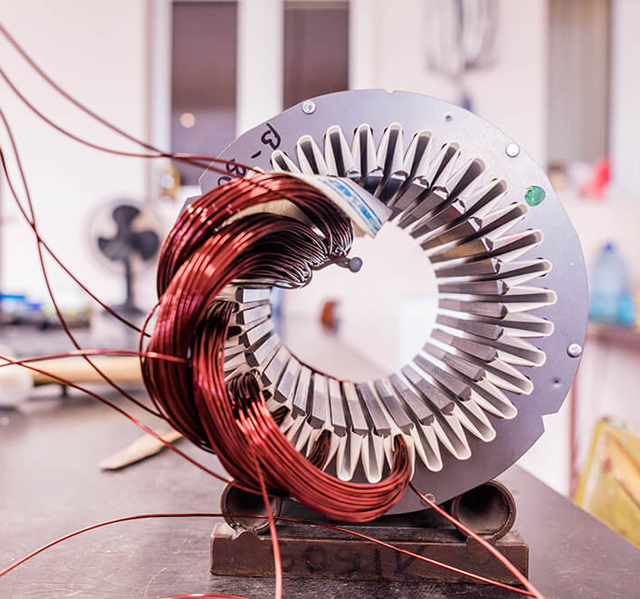

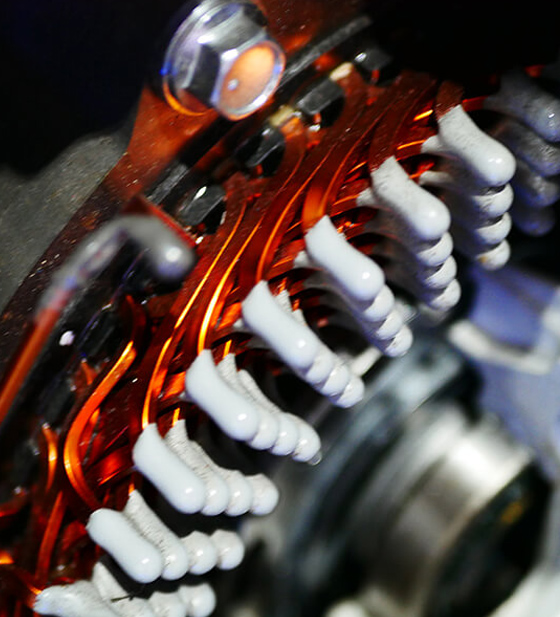

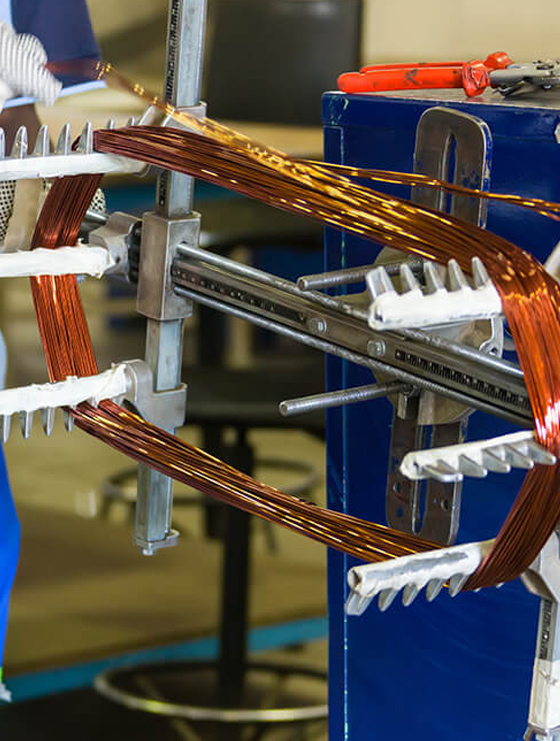

Coils provide the magnetic field of motors, transformers, and generators, and are used in the manufacturing of loudspeakers and microphones. The shape and dimension of the wire used in a coil winding are designed to fulfill a specific purpose.

Parameters such as inductance, energy loss ( Q factor), insulation strength, and strength of the desired magnetic field greatly influence the design of coil windings.

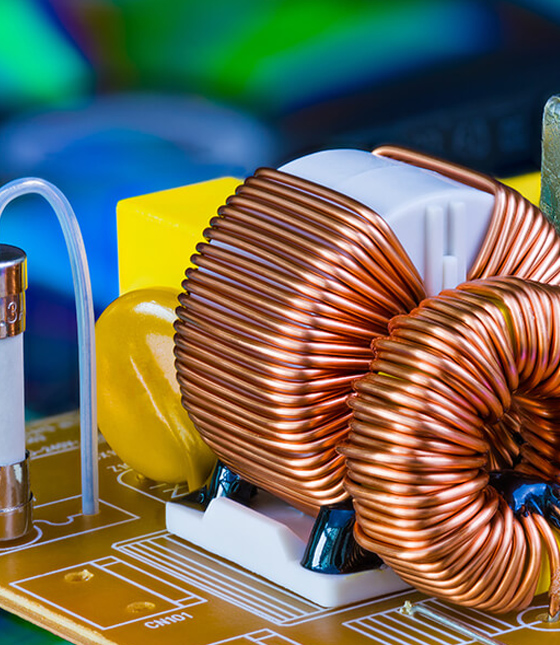

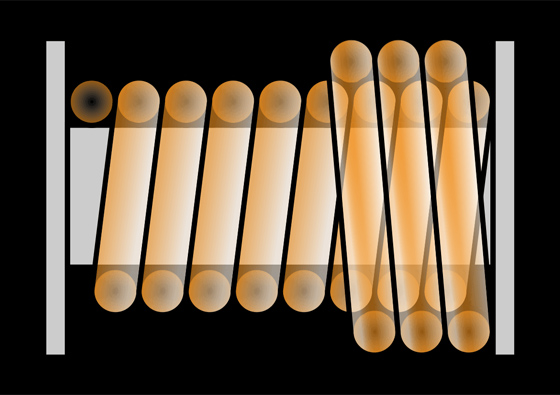

Efficient coils minimize the materials and volume required for a given purpose. The ratio of the area of electrical conductors, to the provided winding space is called “fill factor”. Since round wires will always have some gap, and wires also have some space required for insulation between turns and between layers, the fill factor is always smaller than one. To achieve higher fill factors, rectangular, square or flat wire can be used.

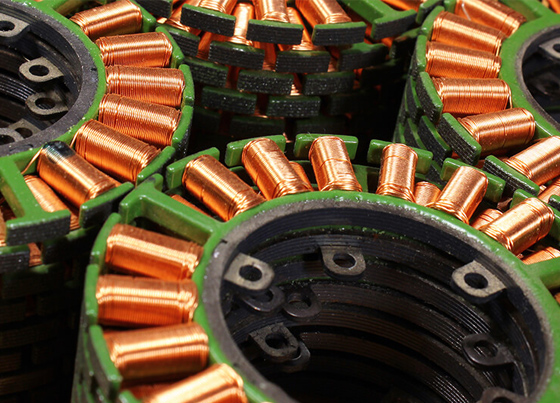

MWS skilled technicians produce the highest-quality magnet wire used in custom windings. To speak with a sales representative, contact us regarding your requirements.