Thin and of light construction, this range provides seamless belts with excellent dimension consistency which are energy saving, highly accurate, ultra-flexible and abrasion resistant, anti-static, low noise and maintenance free.

Thin and of light construction, this range provides seamless belts with excellent dimension consistency which are energy saving, highly accurate, ultra-flexible and abrasion resistant, anti-static, low noise and maintenance free.

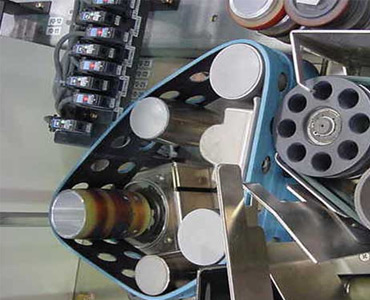

Our SEB™ (Super Endless Belt) range is installed in banking equipment such as ATMs, postal sorting machines, office equipment, printing machines, paper handling applications, ticket dispensers, check weighers and centrifugal drives.

| BELT TYPE | CONVEYING SURFACE | DRIVING SURFACE | MATERIAL (TOP/BOTTOM) | TENSION MEMBER | MAIN APPLICATIONS | THICKNESS[MM] | SATURATED SHAFT LOAD [N/MM WIDTH] | MINIMUM PULLEY DIAMETER[MM] |

|---|---|---|---|---|---|---|---|---|

| SE-XA-PB |  |

|

NBR/NBR | Polyester Cord |

|

1.1 | 7.4 (at 1 % elongation) | 15 |

| SE-A-PB |  |

|

NBR/NBR | Polyester Cord |

|

1.2 | 14.7 (at 1 % elongation) | 15 |

| SE-A-OBA |  |

|

NBR/NBR | Polyester Cord |

|

1.2 | 14.7 (at 1 % elongation) | 15 |

| SE-B-PSS |  |

|

NBR/NBR | Polyester Cord |

|

1.4 | 29.4 (at 1 % elongation) | 25 |

| SE-D-PB |  |

|

NBR/NBR | Polyester Cord |

|

1.7 | 29.4 (at 1% elongation) | 35 |

| SE-D-PSS |  |

|

NBR/NBR | Polyester Cord |

|

2.3 | 29.4 (at 1% elongation) | 35 |

| SE-GS-OC |  |

|

CR/CR | Glass Cord |

|

0.75 | 14.7 (at 0.3 % elongation) | 20 |

| SE-A-NR |  |

|

Natural Rubber/CR | Polyester Cord |

|

2–14 | 7.35 (at 0.5 % elongation) | *1 |

| SE-A-WN |  |

|

Natural Rubber/CR | Polyester Cord |

|

2–12 | 7.35 (at 0.5 % elongation) | *1 |

| SE-A-WN-F |  |

|

Food Grade Natural Rubber/CR | Polyester Cord |

|

2–12 | 7.35 (at 0.5 % elongation) | *1 |

| SE-XA-PGG-F |  |

|

Food Grade NBR/Food Grade NBR | Polyester Cord |

|

1.15 | 3.7 (at 1% elongation) | *1 |

| BELT TYPE | CONVEYING SURFACE | DRIVING SURFACE | MATERIAL (TOP/BOTTOM) |

TENSION MEMBER | MAIN APPLICATIONS | THICKNESS[MM] | SATURATED SHAFT LOAD [N/MM WIDTH] | MINIMUM PULLEY DIAMETER[MM] |

|---|---|---|---|---|---|---|---|---|

| SE-G15-SBU |  |

|

MPU/MPU | Polyester Fabric |

|

0.65 | 1.47 (at 2 % elongation) | 6 |

| SE-G15-LGYU |  |

|

MPU/MPU | Polyester Fabric |

|

1.2 | 1.47 (at 2 % elongation) | 10 |

| SE-G30-LBU |  |

|

MPU/MPU | Polyester Fabric |

|

1.0 | 2.94 (at 2 % elongation) | 10 |

| SE-F50-SBK |  |

|

MPU/MPU | Polyester Fabric |

|

0.8 | 4.9 (at 2 % elongation) | 15 |

| SE-F50-SBU |  |

|

MPU/MPU | Polyester Fabric |

|

0.8 | 4.9 (at 2 % elongation) | 10 |

| SE-F50-LBU |  |

|

MPU/MPU | Polyester Fabric |

|

1.0 | 4.9 (at 2 % elongation) | 15 |

| SE-H50-LIF |  |

|

Fluoroelastomer/Fluoroelastomer | Heat resistant Fabric |

|

1.0 | 4.9 (at 2 % elongation) | 15 |

| SE-H50-SIF |  |

|

Fluoroelastomer/Fluoroelastomer | Heat resistant Fabric |

|

0.7 | 4.9 (at 2 % elongation) | 15 |

| SE-F100-LBU |  |

|

MPU/MPU | Polyester Fabric |

|

1.0 | 4.9 (at 2 % elongation) | 15 |

| SE-F100-SBUK |  |

|

Fabric/MPU | Polyester Fabric |

|

0.8 | 7.8 (at 2 % elongation) | 10 |

| BELT TYPE | CONVEYING SURFACE | DRIVING SURFACE | MATERIAL (TOP/BOTTOM) | TENSION MEMBER | MAIN APPLICATIONS | THICKNESS[MM] | SATURATED SHAFT LOAD [N/MM WIDTH] | MINIMUM PULLEY DIAMETER[MM] |

|---|---|---|---|---|---|---|---|---|

| SE-N-LBU |  |

|

MPU/MPU | Elastic Knit |

|

1.0 | 0.98 (at 5 % elongation) | 10 |

| SE-N-SBR-N |  |

|

MPU/MPU | Elastic Knit |

|

0.65 | 0.98 (at 5 % elongation) | 8 |

| SE-N-SMV1 |  |

|

MPU/MPU | Elastic Knit |

|

0.65 | 0.88 (at 5 % elongation) | 8 |

| SE-N-SMV2 |  |

|

MPU/MPU | Elastic Knit |

|

0.65 | 1.18 (at 5 % elongation) | 8 |