This monofilament polyamide core flat belt range is combined with a wide choice of covers for wear and abrasion resistance. With a skived jointing system using glue, this range provides the ultimate joint reliability for the user.

This monofilament polyamide core flat belt range is combined with a wide choice of covers for wear and abrasion resistance. With a skived jointing system using glue, this range provides the ultimate joint reliability for the user.

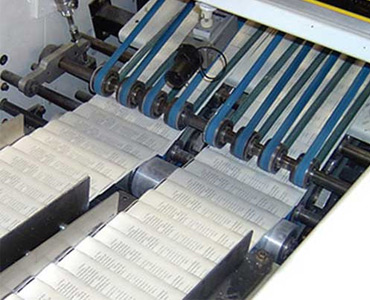

Due to the excellent performance, durability and quality, this range is ideal for demanding applications in the textile, paper processing and printing industries. Customer demands are consistently being fulfilled by new developments using polyamide and own manufactured elastomers.

| BELT TYPE | TOP SURFACE |

BOTTOM SURFACE | MATERIAL (TOP/BOTTOM) | MAIN APPLICATIONS | THICKNESS[MM] | SPECIFIC TENSION (AT 2 % ELONGATION) [N/MM WIDTH] | MINIMUM PULLEY DIAMETER[MM] |

|---|---|---|---|---|---|---|---|

| SG-250 |  |

|

NBR/NBR |

|

0.8 | 3.0 | 25 |

| SG-350 |  |

|

NBR/NBR | 0.95 | 5.2 | 35 | |

| SG-500 |  |

|

NBR/NBR | 1.1 | 7.5 | 50 | |

| SG-750 |  |

|

NBR/NBR | 1.35 | 11.2 | 75 | |

| SG-1000 |  |

|

NBR/NBR | 1.6 | 15.0 | 100 | |

| L-250 |  |

|

NBR/NBR |

|

1.25 | 3.0 | 25 |

| L-350 |  |

|

NBR/NBR | 1.4 | 5.2 | 35 | |

| L-500 |  |

|

NBR/NBR | 1.55 | 7.5 | 50 | |

| L-750 |  |

|

NBR/NBR | 2.2 | 11.2 | 75 | |

| L-1000 |  |

|

NBR/NBR | 2.45 | 15.0 | 100 | |

| L-1500 |  |

|

NBR/NBR | 2.95 | 22.5 | 150 | |

| L-2000 |  |

|

NBR/NBR | 3.45 | 30.0 | 200 | |

| M-250 |  |

|

NBR/NBR |

|

2.2 | 3.0 | 25 |

| M-350 |  |

|

NBR/NBR | 2.35 | 5.2 | 35 | |

| M-500 |  |

|

NBR/NBR | 2.5 | 7.5 | 50 | |

| M-750 |  |

|

NBR/NBR | 2.75 | 11.2 | 75 | |

| M-1000 |  |

|

NBR/NBR | 3.0 | 15.0 | 100 | |

| M-1500 |  |

|

NBR/NBR | 3.5 | 22.5 | 150 | |

| M-2000 |  |

|

NBR/NBR | 4.0 | 30.0 | 200 | |

| H-500 |  |

|

NBR/NBR |

|

3.5 | 7.5 | 50 |

| H-750 |  |

|

NBR/NBR | 3.75 | 11.2 | 75 | |

| H-1000 |  |

|

NBR/NBR | 4.0 | 15.0 | 100 | |

| H-1500 |  |

|

NBR/NBR | 4.5 | 22.5 | 150 | |

| TFL-6S |  |

|

NBR/NBR |

|

2.25 | 11.5 | 60 |

| TFL-7S |  |

|

NBR/NBR | 2.4 | 15.0 | 75 | |

| TFL-10S |  |

|

NBR/NBR | 2.6 | 19.5 | 100 | |

| TFL-12S |  |

|

NBR/NBR | 2.85 | 14.5 | 125 | |

| TFL-15S |  |

|

NBR/NBR | 3.1 | 30.0 | 150 | |

| TFL-18S |  |

|

NBR/NBR | 3.35 | 34.0 | 175 | |

| XH-3S-3 |  |

|

Soft NBR/Soft NBR |

|

2.85 | 3.4 (at 1 % elongation) | 50 |

| XH-3S-4 |  |

|

Soft NBR/Soft NBR | 3.85 | 3.4 (at 1 % elongation) | 60 | |

| XH-3S-6 |  |

|

Soft NBR/Soft NBR | 5.85 | 3.4 (at 1 % elongation) | 80 | |

| XH-500-3 |  |

|

Soft NBR/Soft NBR | 3.0 | 3.8 (at 1 % elongation) | 50 | |

| XH-500-4 |  |

|

Soft NBR/Soft NBR | 4.0 | 3.8 (at 1 % elongation) | 60 | |

| XH-500-5 |  |

|

Soft NBR/Soft NBR | 5.0 | 3.8 (at 1 % elongation) | 70 | |

| XH-500-6 |  |

|

Soft NBR/Soft NBR | 6.0 | 3.8 (at 1 % elongation) | 80 | |

| XH-750-3 |  |

|

Soft NBR/Soft NBR | 3.0 | 5.6 (at 1 % elongation) | 60 | |

| XH-750-4 |  |

|

Soft NBR/Soft NBR | 4.0 | 5.6 (at 1 % elongation) | 80 | |

| XH-750-6 |  |

|

Soft NBR/Soft NBR | 6.0 | 5.6 (at 1 % elongation) | 90 | |

| XH-500-3-F |  |

|

Soft NBR (Food Grade)/Soft NBR (Food Grade) |

|

3.0 | 3.8 (at 1 % elongation) | 50 |

| XH-500-4-F |  |

|

Soft NBR (Food Grade)/Soft NBR (Food Grade) | 4.0 | 3.8 (at 1 % elongation) | 60 | |

| NRT-0 |  |

|

NBR/Fabric |

|

5.5 | 0.65 (at 1 % elongation) | 100 |

| NRT-100 |  |

|

NBR/Fabric |

|

4.5 | 3.0 (at 0.5 % elongation) | 50 |

| NRT-300 |  |

|

NBR/Fabric | 6.5 | 3.0 (at 0.5 % elongation) | 100 | |

| NRT-500 |  |

|

NBR/NBR | 6.0 | 3.8 (at 1 % elongation) | 90 | |

| RT-300 |  |

|

NBR/Fabric |

|

7.0 | 3.0 (at 0.5 % elongation) | 100 |